Equipment-ICT

Equipment-ICT

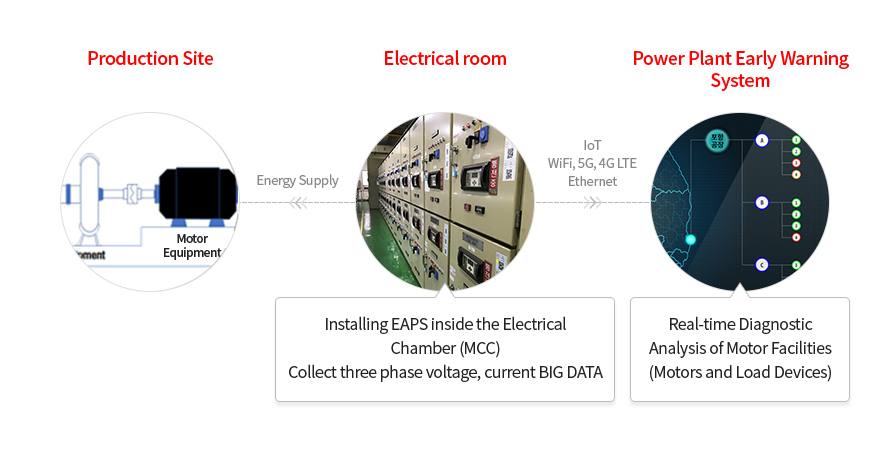

Introduction to EAPS

A new technology that accurately diagnoses the current status of motors and load devices by simply collecting BIG DATA of voltage/current in the electrical room (MCC). It is very convenient compared to attaching vibration sensors at the production site and analyzes the efficient use of energy.

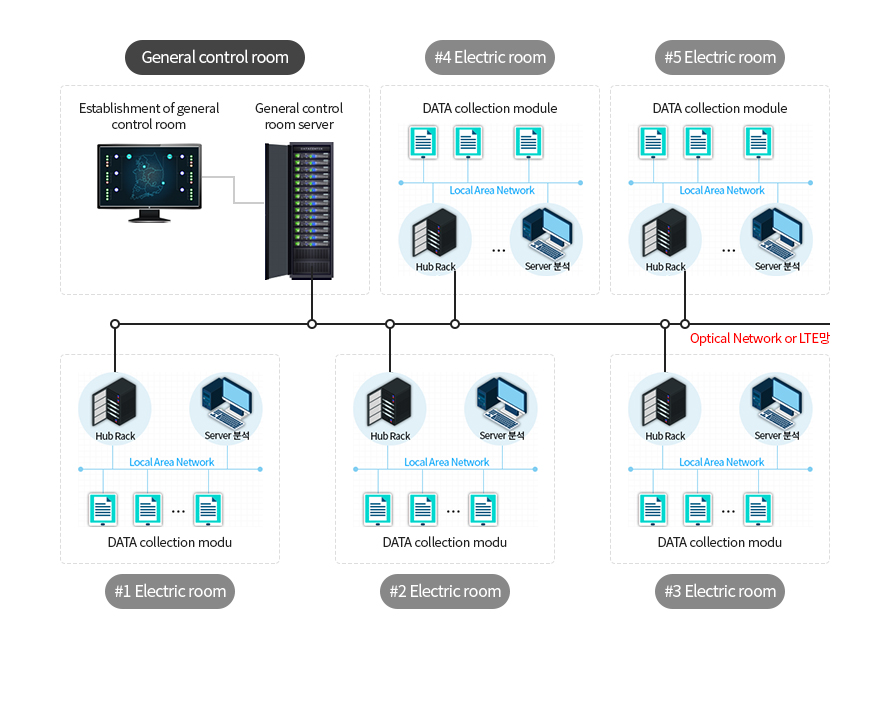

The number of analysis servers may be reduced depending on the customer's installation environment.

The number of analysis servers may be reduced depending on the customer's installation environment.

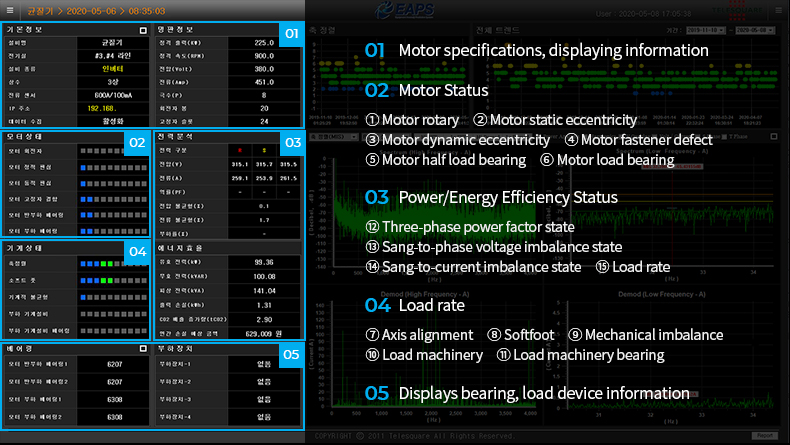

Diagnostic items

-

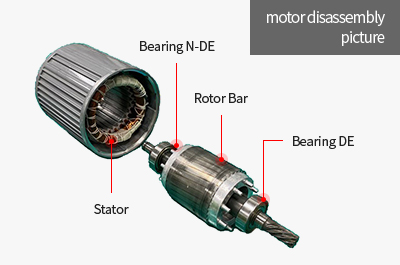

MOTOR

- stator state

- rotor state

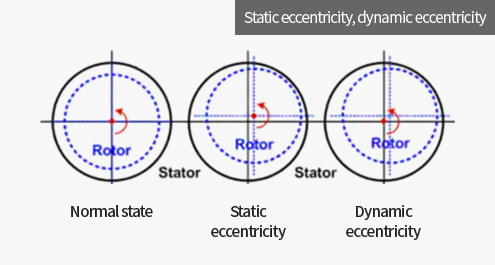

- Static and dynamic eccentricity

- Load side, empty load side bearing

-

Equipment

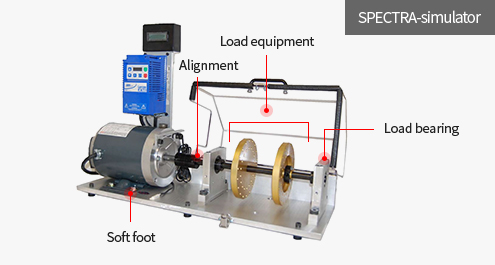

- axis alignment state

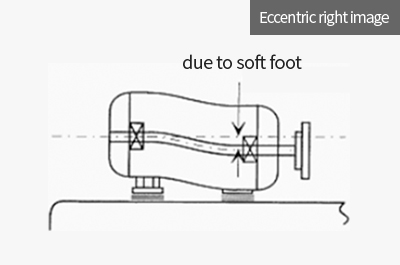

- soft foot state

- hardware condition

- hardware bearing condition

-

Energy Efficiency

- Power factor

- V-P unbalance

- I-P unbalance

- Load rate

-

Measures provided

- 3-phase voltage

- 3-phase current

- active power

- reactive power

- Apparent power

- output loss

Diagnostic items

- motor rotor fault

- Motor stator fault: A fault in the stator that surrounds the motor rotor with an electromagnetic field.

- Defective motor load bearing: Defective bearing under load

- Defective motor anti-load bearing: Defective bearing under load

- Shaft alignment defect, soft foot defect, load machine equipment condition, load machine equipment bearing condition

- Static eccentricity: A defect in which the motor rotor rotates off-center.

- Dynamic eccentricity: A defect in which the motor rotor rotates at a center point but has eccentricity.

- Power/Energy Efficiency Status

Diagnostic itemsDiagnostic HMI Screen Configuration

It shows the overall status of motor facilities by region.

Individual and motor equipment displays analytical diagnostic results and details.

Expected Effects of Using EAPS

-

Improve motor facility management through real-time analysis and diagnosis of motor facilities

Real-time monitoring and maintenance of motor facilities can be performed according to the guide by monitoring real-time analysis diagnostics and reporting diagnostic results on 15 items of motor facilities.

-

Improve the number of years of use of motor facilities

By diagnosing and managing motor facilities in real time, motor failure and damage can be prevented and the number of years of use of motor can be improved.

Generally, the number of years of use of motor facilities is 10 years, but depending on the environment and management of use, they are replaced about every two years due to failures and damage. EAPS, a real-time diagnostic management system, can improve the number of years of use of motor facilities.

-

Energy savings for motor facilities

Real-time monitoring of motor facilities enables efficient maintenance to improve energy efficiency and reduce power energy consumption by using motor facilities in the best condition.

-

Streamline inspection of motor facilities

Up to one to five motor facilities can be inspected per day during on-site inspections in pairs, but time and cost for maintaining motor facilities can be saved by establishing a more efficient inspection plan through real-time monitoring.

-

Improve motor facility maintenance collaboration

By providing diagnostic results on electrical and mechanical properties of motor facilities, time and cost can be saved by improving the collaborative process of maintaining motor facilities between departments such as electrical and mechanical teams.