Equipment-ICT

Equipment-ICT

Drive and change in magnetic flux of power facilities

Electric energy supplied to the motor is converted to kinetic energy and drives the production facility, which causes magnetic flux changes in the motor or mechanical device, and can check the abnormal peak during FFT conversion.

Build a Smart Factory

By connecting the EAPS module in the mcc, it can collect BIG DATA of three-phase electrical signals from moti and mechanical equipment and analyze and diagnose BIG DATA through IOT, completing a smart factory that can predict and preserve motor facilities.We will also establish a control center that can monitor the status of motor facilities in factories around the world in real time through global network and cloud services.

Big Data Handling

Voltage/current BIG DATA acquisition and diagnostic

analysis of motor equipment

- Ultra-precision data collection with 16bit Analog to Digital technology

and up to 128/Hz sampling technologies - Diagnostic analysis of 25MB of Big Data for 3 minutes

- Precision diagnosis with approximately 30,000 defective frequency databases

and AI algorithms - Patent Retention of Source Technology

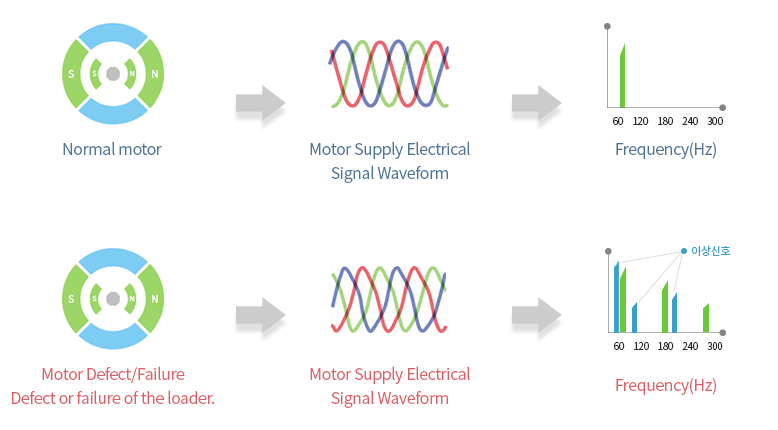

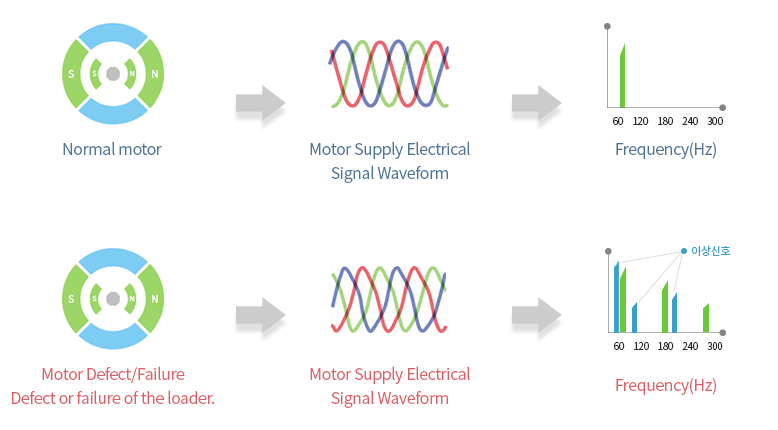

Principle of Diagnostic Analysis

Analysis of Abnormal Frequency with fft Transformation

Changes in the motor's load, electrical/mechanical defects, etc. cause a small change in voltage/current, which is the motor's power, and determine the cause of the defect by separating the harmonic components of the 60 Hz power frequency component and the breakdown frequency.